The Process Behind Water-Resistant Madit Coasters

- madit.uk

- Mar 14, 2025

- 2 min read

Updated: Apr 8, 2025

Creating a set of premium coasters isn’t just about cutting wood—it’s a careful process of refinement, precision, and patience. Each step ensures the final piece is as elegant as it is functional. Here’s how they come to life:

1. Preparing the Wood

It all starts with selecting a high-quality wooden plank. Any factory stickers or residues are carefully removed before the surface is smoothed out, ensuring a clean foundation to work with.

2. Precision Cutting & Detailing

Each coaster is cut to size with precise measurements, accounting for the natural kerf of the blade. A subtle groove is routed into the surface, adding both texture and design while maintaining a seamless look. The edges are then softened for a refined feel.

3. Sanding & Conditioning

To achieve a smooth, flawless surface, the wood undergoes multiple rounds of sanding. Before staining, a pre-stain conditioner is applied to ensure an even and rich finish. This is left to dry before moving to the next step.

4. Staining & Finishing

Staining is a layered process, allowing time for each coat to absorb and dry properly before applying the next. This enhances the depth of color and ensures a long-lasting finish.

5. Protective Coating

Once stained, the coasters are treated with layers of tung oil, with each application requiring a full day to dry. This enhances durability and creates a smooth, water-resistant surface.

6. Final Polish

The last step is a careful polish, bringing out the richness of the wood while ensuring the surface feels premium to the touch. Another day of drying completes the process, leaving behind a beautifully crafted set of coasters, ready to enhance any space.

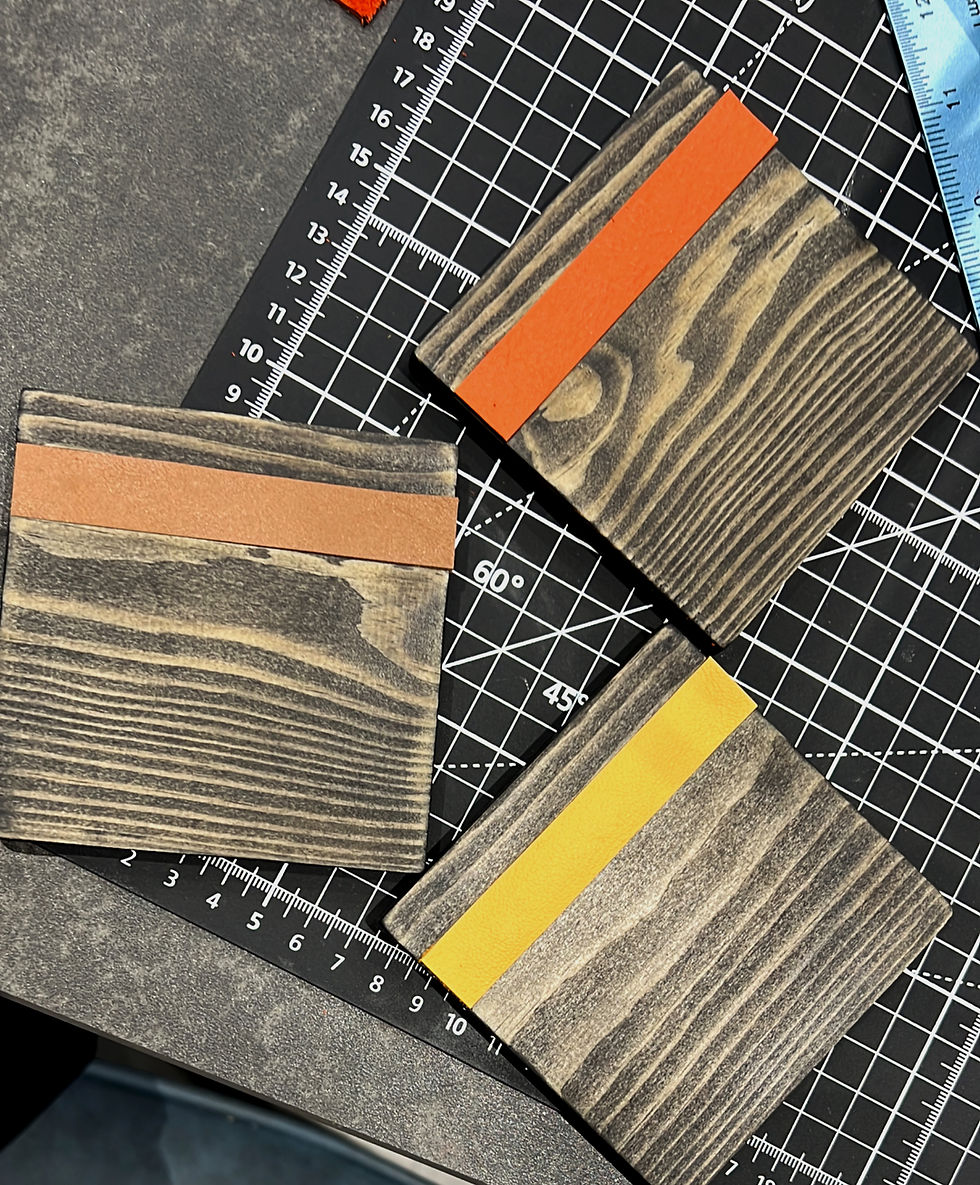

7. Cutting & Fitting the Leather Strips

Leather strips are measured and cut to fit the groove precisely. The strips are pressed into place, ensuring they sit flush with the wood’s surface, providing a plush finish. The leather edges are trimmed and conditioned for a smooth, premium feel. At the end a waterproof coating is applied to the leather.

From start to finish, it’s a multi-day process—one that ensures each piece meets the highest standards of quality and craftsmanship.

Comments